About Floor Decals

Floor decals are a great opportunity to add additional branding to your event or promotion. They can be great for way finding, sponsorship opportunities, special promo signage, and much more.

A variety of substrates to suit all surfaces:

- Non-slip finish.

- Many substrates to choose from to suit different needs.

- Suitable to be used in both indoors and outdoors.

- Full on-site installation service provided.

We have non slip certifications for all floor decals and can provide them on request.

Floor decals are single use only and depending on the size, choice of substrate, and the foot traffic on the chosen surface, can last from a few hours to many months.

We can also provide installation service for this product.

Why Our Floor Decals

Australian Made

Our Australian made products give you the advantage of superior quality and shorter turnaround times. You are also supporting the Australian economy and local jobs.

Fast Turnaround

If you have deadline we’ll help you meet it. With our large in house production facility, we can produce projects of any size in short notice.

Experience

Our industry experience gives us a virtual 6th sense when it comes to looking at briefs and identifying issues or opportunities. Our staff will provide insightful recommendations , honest advise and finally delivering on or exceeding expectations.

Product Specs

Surfaces

Concrete

Carpet

Tiles

Floorboards

Road

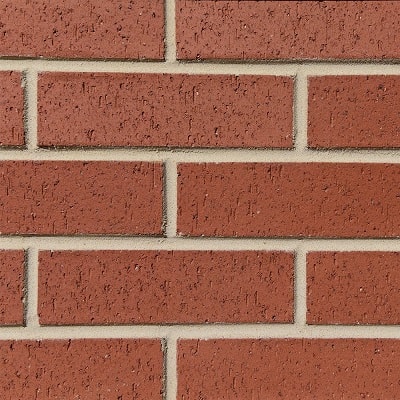

Brick

Materials

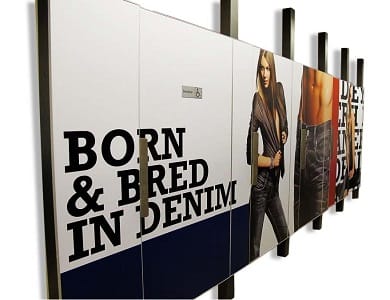

Removable SAV with non-slip laminate

Indoor floor applications including carpet, tiles, floorboards and concrete.

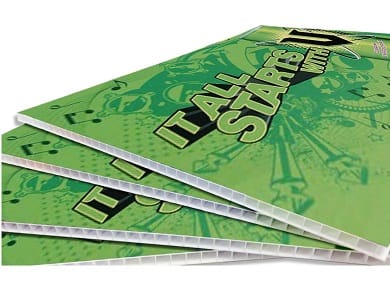

Texwalk (385 GSM)

Indoor floor applications including carpet, tiles, floorboards and concrete. No overlaminate required.

Road SAV (390 GSM)

Textured outdoor surfaces including road, asphalt, concrete, pavers and brick walls. No overlaminate required.

Applications

| Materials |

Slip Rating |

Concrete |

Carpet |

Tiles |

Floorboards |

Road |

Brick |

| Removable SAV with non-slip laminate |

R9 |

|

|

|

|

|

|

| Texwalk (385 GSM) |

R10 |

|

|

|

|

|

|

| Road SAV (390 GSM) |

R12 |

|

|

|

|

|

|

Non Slip Certification

Australian / New Zealand Standards 4586:2004 non slip approved

Print Process

Solvent

Direct printing is where a dye is used to add colour directly to fabric.

UV curable

Screen printing uses a template with gaps in it for the design, which is burned onto a screen with exposure light. Ink is pushed into the pattern, leaving colour on the fabric.

Latex

One of the newest methods is digital fabric printing, done with inkjet technology. The fabric is fed through a printer, which applies the design through thousands of tiny ink drops.

Selby's Worry-Free Guarantee

Quality, punctuality and reliability. Your business deserves all three.

In an industry where trust is a must, Selby's is the partner you can rely on.